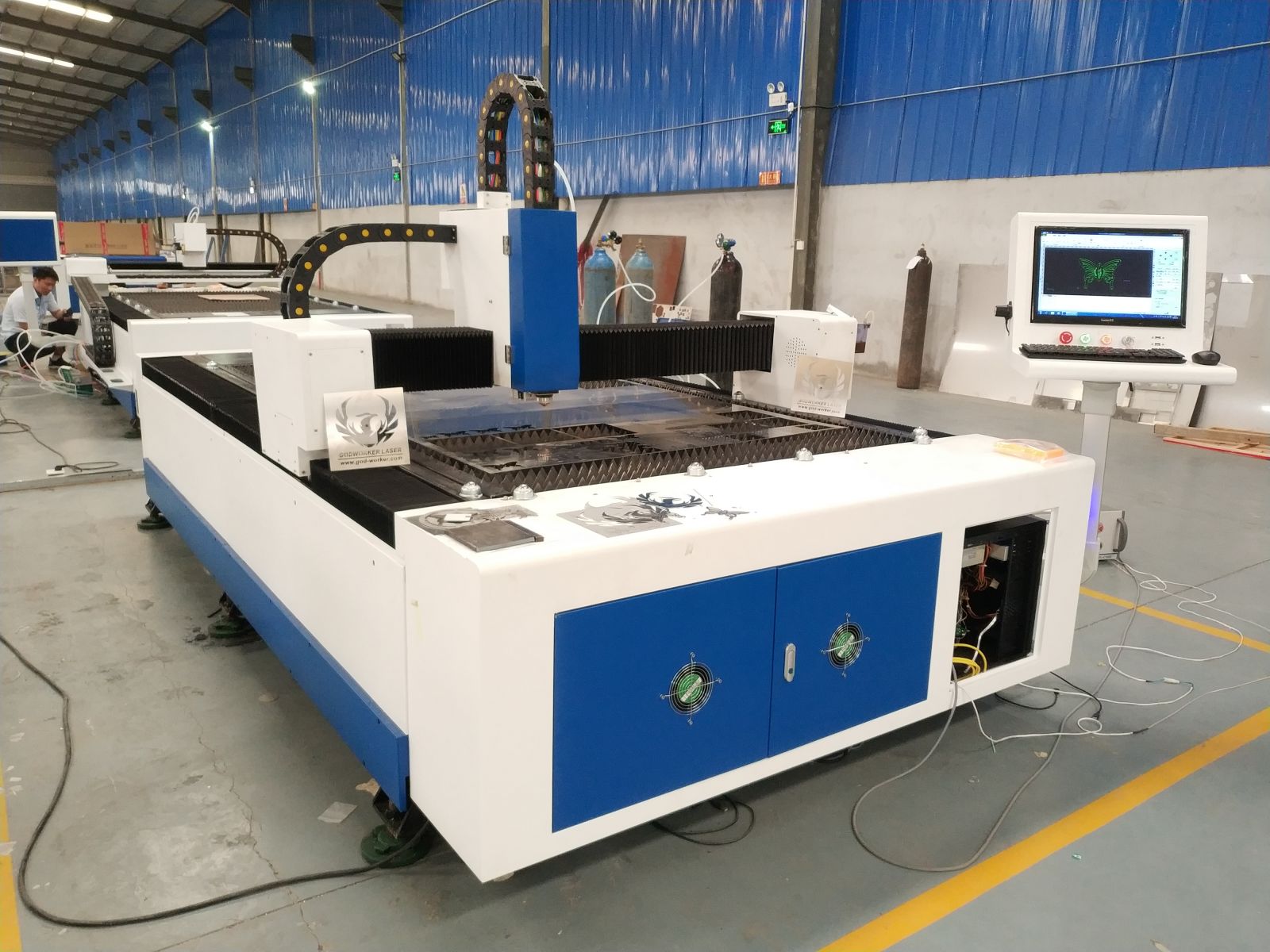

GW-1530 raycus 1500W fiber laser cutting machine

Product Name:

GW-1530 raycus 1500W fiber laser cutting machineModel No.:

GW-1530Minimum Order:

1

Product Abstract:

1.Delivery time: 20-30 working days 2.Pay for 30% deposit, 70% balance be paid before shipping; 3.Warranty: 2 years, within time free Maintenance and repair; 4.Package: plywood case with steel tube;

- Product Description

Introduction:

Support different images format as Al, DXF, PLT, Gerber, can read standard ISO G codes from MaterCam, Type3 such nesting software.

Automatically optimization when open or lead in DXF file, like delete repeated line, merge connected lines, recognize in/out cutting file and file sorting out.User can decide to manually do above work, or let controller do it automatically.

Support conventional picture edit functions

Following what you see is what you get, to set lead in/out, kerf compensation, merge, bridge, over burning, save gap ….etc

Unique function of Preview of cutting work flow.

Support segmental pierce, Progressive pierce, Pre-pierce, power pierce,,, separately setting output laser watt, frequency, laser type, air type, pressure, auto cutting height during pierce and cutting.

Support to set separate lead in/out speed according to adjustment of laser power.

Big storage, allowing user to save all cutting parameters to use it again on same material.

Breakpoint recovery, CNC can return to the point where the cutting stopped, allowing partial file cutting. It can go to any point to start there after stop or pause.

Same software can support round tube cutting and plate cutting, programming is same, and support intersect cutting.

Support to cut at set height, automatically seek edge, and start from outside of workpiece, or lift up when torch is out of workpiece.

Powerful expanding capability, over 15 PLC process programming, over 30 programmable processes.

Input/output and alarm input are programmable, support wireless remote control, and support internet ……

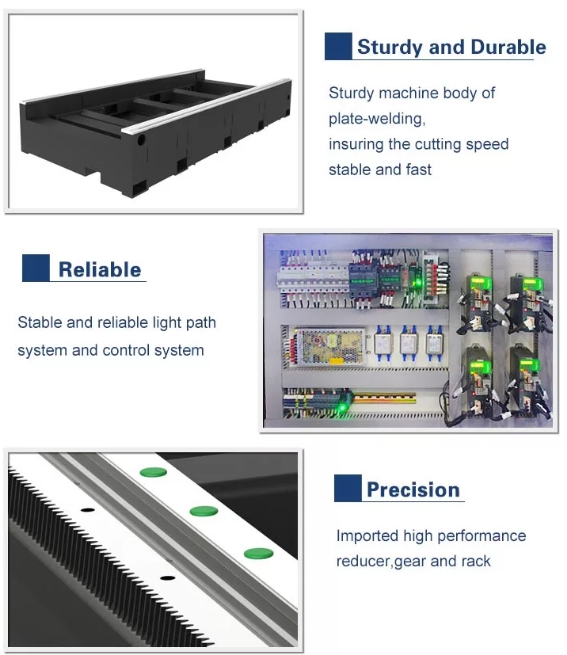

Equipment features:

· Contracture compact, small floor area.

· Stability and reliability of light path system and control system.

· Humanizing design, convenient operation.

· Ultra low cost, low operating cost, laser consumes only 0.5-1.5 degrees per hour.

· High performance and low use-cost; imported fiber laser of the original factory packaging, stable performance, the service life of up to more than 100 thousand hours.

· High cutting efficiency and quality, no noisy, high cutting speed and efficiency, Cutting speed is up to dozens of meters per minute when cutting sheet. Less deformation, smooth appearance and beautiful, cutting edge is high at quality.

· High precision Yaskawa servo motor, HIWIN Linear Rial and YYC Gear Rack imported ensure the efficiency and accuracy, increasing the stability and reliability greatly.

Application Industry:

Fiber laser cutting machine has been widely used in sheet metal cutting and processing, house electrical appliances manufacturing, Precision parts , decoration and advertisement.It is your best choice for cutting stainless steel, carbon steel , mild steel and sheet aluminum.

Parameter:

Model

GW-1530

Working Size

1500x3000mm

Laser Type

Raycus Fiber Laser Generator

Laser Wavelength

1070 nm

Laser Output Power

1000W / 1500W

Cutting Thickness

Within 14mm steel

Max Cutting Speed

1000mm/min

Position Accuracy

<±0.01mm

Minimum Line width

<0.12mm

Cooling System

Industry chiller

Driving System

Japan Yaskawa Servo motor and drivers

Working Voltage

380V; 50Hz/60Hz

Transmission

HIWIN Linear Rail + Gear rack

Power Adjustment

0-100% controlling, no segment

(0-100% adjusting by software)

Aiming Position

Red-light position

Blowing System

Cabinet exhaust fan

Minimum Character

Chinese character 2.0mm, crisscross-row 1mm

Working Environment

Temperature: 0-45°C Humidity: 5%-95%

(congeal-water removed)

Protection level

IP54

Machine weight

3.5 Tons

Size L*W*H(mm)

4300*22700*1600mm

A. Saving water and electricity costs:

Fiber lasers have excellent thermal performance, high efficiency electro- optical, saving water, particularly important is long-term maintenance-free use, can save a lot of money and time to maintain and improve work efficiency.

B: Low price:

All optical fiber laser consists of fiber and fiber optic components, Constitute fiber lasers cost major part is Semiconductor pump laser. IPG has a semiconductor laser module production line, independent research, development & production of single junction semiconductor module, can be lower than our competitor's price.2.2 Control box:

Fiber laser cutting machine control box need to individually configured to reduce interference, and easy to maintenance.

2.3 laser cutting head:

Import Raytool laser cutting head, and also can up & down with Z axis.The height of the cutting head servo sensor uses the principle of capacitive sensing monitoring, providing a steady and rapid automatic cutting height adjustment function. Supporting the design of a wide range of nozzles to apply to almost any focal length lenses. It has the characteristics of confocal fixed-length body can make it work head equipped with different focal length optics. Its focal length and nozzle height can be adjusted flexibly, lenses and coaxial nozzle adjustments include XY direction.

2.4 Safety Protection System:

The device is small and medium- power laser cutting equipment, laser radiation on the human body has some damage, so the whole system of security measures becomes extremely important .

Laser protection section:

1. Laser part marked with an icon to indicate where the laser output , avoid direct laser to cause injury ;

2. Lasers are grounded outer part of the case , to avoid leakage enclosure result in personal injury ;

3. Is the operator with appropriate laser protective eyewear , the entire operation must be maintained to wear protective glasses ;

Before operating the equipment, protective equipment must be checked for wear ;

4. In the equipment energized at any time does not permit the use of laser eye contact head ;

5. Laser equipment with emergency stop switch, the laser can be stopped immediately in case of emergency , and the laser power ;

6. Laser equipment operation, providing three-color status indication , etc., can display laser equipment working condition ;

The external part of the transmission fiber protection:

1. External workstation transmission fiber parts, selection of high quality imported slide pulley and limit device to guide laser fixed and cable ;

2. Transmission fiber laser protective materials from special protective cover to protect against laser leak ;

3. Transmission fiber protective cover portion is equipped with a laser leakage protection , because if the laser fiber breakage resulting in leakage , laser leak into the laser sensor can monitor leaks , leaks immediately if found to transmit signals to the control center , the control center to stop the laser light and alarm equipment.

3.1 Consumables:

1. Protector mirrors:2pcs/month,$60/pc,500 hours/pc,

2. Cost per hour:$60÷500=$0.12/hour

3. Ceramic ring:1pc/year,$300/pc, 7200 hours/pc,

4. Cost per hour:$300÷7200=$0.04/hour

5. Cutting nozzle:$17/pc,400 hours/pc

6. Cost per hour: $17÷400=$0.04/hour

3.2 Cutting speed

Laser

Materials

Thickness / mm

Speed / mm/s

Watts

Gas

1000W

S.S

1

350

100%

N2

2

100

3

42

4

17

5

10

C.S

1

250

98%

O2

2

92

3

67

4

42

5

29

6

25

8

15

10

10

Aluminum

1.5

100

100%

N2

2.5

59

3

25

Copper

1

334

100%

N2

2

67

3

25

1500W

S.S

1.5

200

100%

N2

2

150

3

55

4

36

5

20

6

15

C.S

1

150

80%

O2

2

80

3

60

98%

4

50

5

40

6

25

80%

8

20

98%

10

18

12

15

14

12

80%

Aluminum

1.5

180

100%

N2

2

80

2.5

60

3

40

4

25

Copper

1

180

2

60

3

20

4

10

Machine Parts:

Samples:

Package:

- Related Products

- GW-3015F fiber laser cutting machine

- GW-3015/2040GA IPG 2000W fiber laser cutting machine,cnc laser machine,metal laser cutting machine

- GW-1530 raycus 1500W fiber laser cutting machine

- 3015 Heavy duty fiber laser cutting machine with IPG 1500W, 2000W, 3000W, 4000W

- 6080 small size fiber laser cutting machine, mini fiber laser cutting machine

- [Return Home] [Print] [Go Back]

Products Search

Brand Zone

Contact Us

Contact Person:

Godwin GaoTel:

+8615553103090 ; 13296418707Fax:

E-mail:

info@god-worker.com- sales@god-worker.com