New design 1625 1630 oscillating knife cutting machine

Product Name:

New design 1625 1630 oscillating knife cutting machineModel No.:

GW-1625N /1630NBrand:

GodworkerMinimum Order:

1

Product Abstract:

New design structure, more stable and heavy than before. Faster speed running, low noise (< 38.6db). Adopt Germany Igus cable, it has Anti-interference that can make sure machine long time continue working stable.

- Product Description

- New design 1625 / 1630 oscillating knife cutting machine:his new design 1625/1630 round knife cutting machine standard with high speed round knife. It can cut fabric, cloth fold in many layers, can save a lot labor cost. This round knife cutting machine is widely used in garment industry, sofa industry, curtain industry, carpets industry, car seat mat industry, etc.

Features:

CNC Cutting Machine are more stable and solid with steel structure, which are based on a modular design concept that lends them greater flexibility and adaptability than that of any other system on the market.

Automatic search for anchor point and continuously cut the photo polymer rolling materials with non-oscillating tool.

It’s easy to cut different thickness of grey board with precise setting of the various cutting angles.

With the automatic lubrication system (timing, quantitative, fixed), it is for non-stop production.

With high sensitivity anti-collision device and automatic sensor inside, it is security & reliable.

Advantage:

The platform detection device regulates the knife pressure automatically, enabling a level platform and perfect cutting.

Machine can induce draft separately and easily cuts small pieces.

The anti-collision and the built-in auto-sensing devices ensure the security of machine.

High efficiency can be realized without making a high-cost knife model.

Designed for production with small quantities and can save on costs while maintaining speed and accuracy.Technical ParametersModel

GW-1625N / 1630N oscillating knife cutting machine

Working area

2500*1600mm

3000×1600mm

Rated power

12KW

Fixed mode

Flat plate table

Multi-function head

Oscillating knife head / Round knife / V-cut head / Kiss cut head / Penumatic head / Pressure wheel / Spindle for option

Tool configuration

Multiple cutting knives

Safety device

Using infrared sensors, responsive, safe and reliable.

translational velocity

800-1200mm/s

Cutting speed

200-800mm/s(according to different cutting materials)

Cutting thickness

≤100mm(according to different cutting materials)

Cutting materials

Leather, all kinds of clothing flexible material, Sponge composite leather, PVC, soft glass, Silicon, rubber

Repeated accuracy

≤0.1mm

Machenical Precision

Max. 0.02mm

Driving system

Delta servo motors + drivers

Transmission system

Helical gear rack + HIWIN linear rail (X,Y axis 20mm)

Control system

Double 32bit RISC CPU + Huge reparogrammable logic gate arrays FPGA

Operation mode

Operating flat form+Data output control software

Support format

AI, PLT, DXF, CRD, etc

Control Panel

Ruida LCD touch screen

Capacity

4GB

Instruction system

HP-GL compatible format

Voltage

380V +220V, 50/60Hz;

Vacuum pump

7.5KW vacuum pump

9.0KW vacuum pump

Packing size

3350*2150*1600mm

3850*2150*1600mm

Gross Weight

1300KG

1500KG

Samples

Machine DetailsImported knife: using simple replaceable head design concept, according to the actual cutting process and tool head replacement with different functions.

Control Panel: Multi-language for option, easy operate interface.

Driving system: Delta servo motors drives control mode, preset storage knife depth, knife pressure, speed of movement.

Guide rail: Adopt Taiwan HIWIN linear rail and gear rack, it can make sure working high speed and precision.

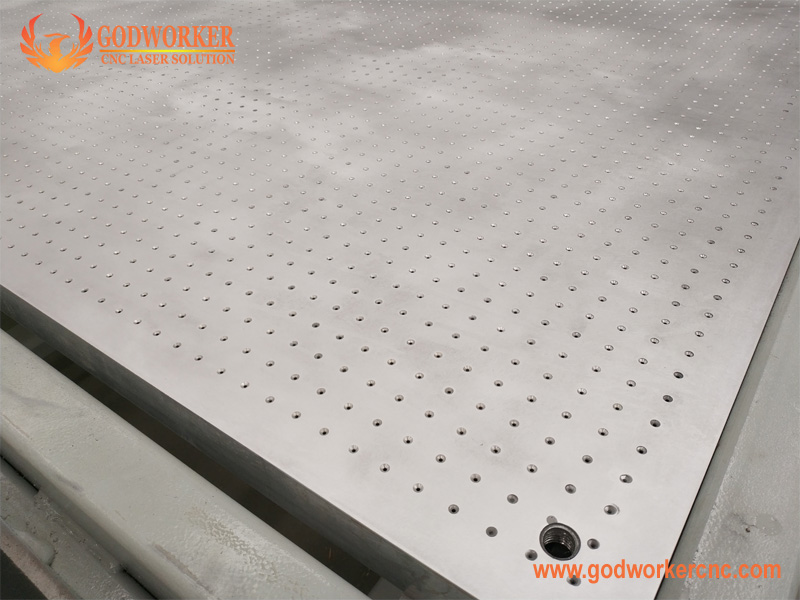

Vacuum table: Adopt sophisticated aluminum sophisticated table design, platform width can be customized size, theoretical length is unlimited; vacuum suction design, software can choose to control 8 suction area.

Imported Germany fiber mat that durable, good permeability, and stable shape.

Vacuum Pump: Adopt strong power 7.5KW air vacuum pump for fixing materials while machine cutting materials.

Safety Sensor: Y axis has 2 sets infrared sensor to protect operator or other human body safety.

Control cabinet: Control board, drivers, breakers.

FAQQ: Are you a factory or Trading company?

A: We are a factory and the one manufacturers of vibrating knife cutting machines in North of China with about 10 years experiences in this field.

Q: Can you customize the machine according to my needs?

A: Yes, we accept the customized machine, our company has an experiencedprofessional design team, we can give you our professional suggestions according to your requirements and design a cost-effective machine for your needs.

Q: What is the difference between your product and the laser cutting machine?

A: 1. Our products are cut with vibrating blades, no laser, no pollution, and create a good working environment for workers.

2. Blade cutting can ensure the edge of material cutting smooth without burning.

Q: Does your price have a discount for dealers?

A: Yes, we have a favorable policies for dealers. Please tell me your order quantity or annual purchase quantity. The price will be adjusted according to the order quantity. For details, please consult our sales staff.

Q: How is your after-sales policies?

A: 1. The machine warranty is 12 months after shipment date. During the warranty period, the main accessories(except the wearing parts) are replaced free of charge because of the quality problems under the normal operation. Others, under improper operation need to pay the parts cost and freight.

2.We have an experienced after-sales team 24h online service and a completafter-sale system. Factory trainning support, Video technical support, online support, Engineers available to service machinery overseas.

3. Inquiries are typically answered within 24 hours.

Q: Can you provide ODM and OEM services?

A: Yes, our R&D team with an average of 10 years experiences, the ODM&OEM service are satisfied with our customers.

- Related Products

- [Return Home] [Print] [Go Back]

Products Search

Brand Zone

Contact Us

Contact Person:

Godwin GaoTel:

+8615553103090 ; 13296418707Fax:

E-mail:

info@god-worker.com- sales@god-worker.com