GW-1325 metal nonmetal laser cutting machine 280W + 60W

Product Name:

GW-1325 metal nonmetal laser cutting machine 280W + 60WModel No.:

GW-1325MPrice:

USD14500Minimum Order:

1

Product Abstract:

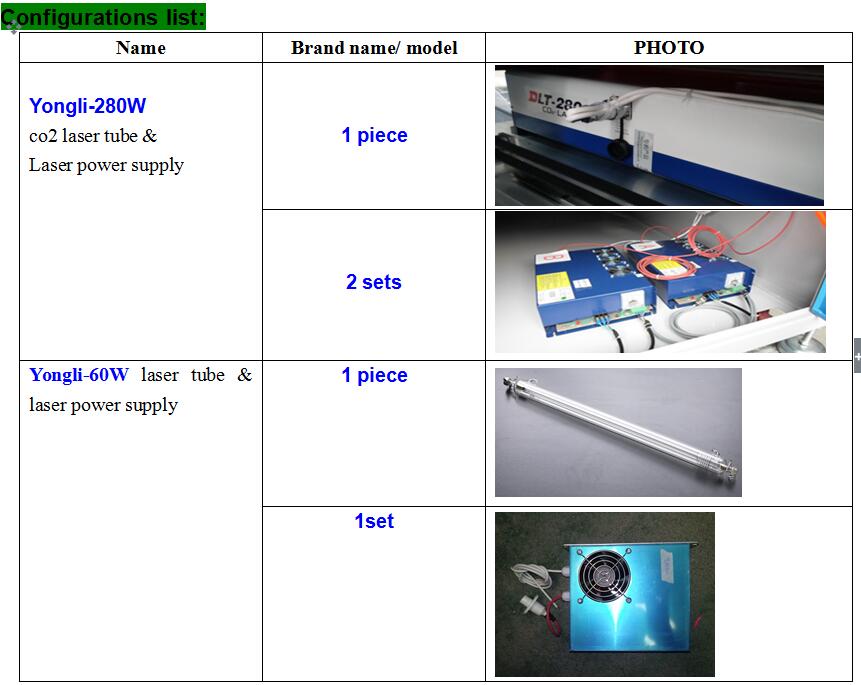

New sollutions for clients, this machine install 2 heads, 280W laser for cutting metal & thickness nonmetal materials, 60W for engraving objects. It can solve that use too strong power tube for engraving to harm laser tube lifetime problem. GW1325 meal nonmetal laser cutting machine: 1. Aluminum Knife table; 2. Machine working size: 1300*2500mm; 3. Laser tube: Yongli-280W + 60W CO2 sealed glass tube; 4. Guide rail: PMI Linear Rail MSA-25R X axis, Y axis MSA-20R; 5. Motor + Driver :Yako stepper motor ; 6. Ruida 6332M DSP control system; 7. Mix auto focus cutting head with sensor and cutting nozzles; 8. Oxygen gas connect equipment; 9. Mirror & lens: Dia 25mm II-VI mirrors, Dia 25mm ZnSe lens; 10. Water chiller CW6000 ; 550W exhaust fan; air compressor; software CD, data line, power line, operate glasses and other machine accessories;

- Product Description

- Godworker New sollutions for clients, this machine install 2 heads, 280W laser for cutting metal & thickness nonmetal materials, 60W for engraving objects. It can solve that use too strong power tube for engraving to harm laser tube lifetime problem.

Features:

1. Mixed-cut: metal-Stainless steel,carbon steel and non-metal-acrylic,board.

2. High precision: Adopt YAKO stepper motor with PMI Linear Rail transmission greatly improve the response speed & cutting precision of equipment, extend the time of using.

3. Constant light system :The machine uses the constant light,achieving high precision cutting of the whole area.

4. High precision and stability: with precision Japan ONK belt & Chinese Taiwan PMI Linear Rail transmission mechanism and optimized the Ruida RDC 6332M system control, it can meet the precision parts processing ,stable dynamic performance, also can work for long hours.

5. The cutting section with good quality: mechanical follow-up cutting head system : cutting head always follow the material to keep the cutting point location unchanged, which insures smooth cutting section without processing again .It can adapt to flat or curved surface sheet cutting.

6. Adopt Yongli / RECI sealed CO2 laser tube, main consumable items are electric energy, water-cooling,auxiliary gas and laser light.

7.Stronger structure 3.2mm steel,easy operation, stable laser device & low maintenance cost.

Applicable materials:

1) Applicable industry:Mainly used for advertising industry (stainless metal and carbon steel),sheet metal industry (carbon steel), packaging industry (die board) and so on .

2) Applicable materials:acrylic, stainless steel ,carbon steel,MDF,die board.

3) Applicable show: metal spectable frame,furniture plate cutting,MDF photo frame cutting, building model cutting.

Parameters:Model

GW-1325M

Engraving and Cutting Area

1300*2500mm

Tube type

CO2 sealed glass tube

Laser wave

10.6um

Laser Power

RECI W6 + 60-100W

Yongli-280W + 60-100W

Cooling

CW5200

CW6000

Engraving Speed

0-60,000mm/min

Cutting Speed

0-30,000mm/min

Reposition Accuracy

±0.01mm

Minimum Character Size

English:1mm ; Arabic numbers:1mm

Resolution

1,000--10,000 dpi

File output mode

2.0 USB interface

Machine Power

<3,800W

Support Format and Software

PLT,DST,DXF,DWG.CDR, AI, Auto CAD, Coreldraw, Photoshop, Metalcut

Table

Knife working table

Working Environment Temperature

0-45°C

Drive system

YAKO stepper motor + Japan ONK belt

Control system

RDC6332M control system

Exhaust smoke system

550W exhaust fan

Working Voltage

220V,50HZ/60HZ

N.W.

1000KGs

G.W.

1200KGs

Warranty time

2 years for machine;10 months for tube

Package

Plywood case with steel tube

Packing size

4300*2260*1500mm

Delivery time

15--20 working days

Samples:

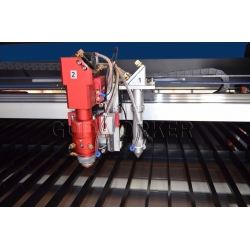

Machine parts details:

Auto focus sensor can keep fixed focus distance while cutting metal. Air blowing device can remove cutting smoke and dust to protect focus lens, nozzles and auto focus sensor. Yako stepper motor provide power for multi head up down auto focus. Strong power head for cutting steel & nonmetal, another one small power head for engraving nonmetal materials.

Each metal and non-metal mixing machine we will be equipped with two sets of metal nozzles,The metal cutting nozzle has a smaller hole diameter and a higher height, while the non-metal cutting nozzle has a larger hole diameter and a lower height.

Adopt Japan top brand ONK belt and YAKO stepper motor and driver, it can run reliable and has high precison.

The control cabinet mainly includes a Ruida 6332M control board card, a Live-Focus-System control board card, four drivers, and a 48V supply to power the driver, a 24V supply to power the control card, two voltage filter, Schneider breaker.

Adopt S&A water chiller, It can continue to cool the laser so that the laser can continue to work efficiently.

Yongli / RECI combined CO2 laser tube, able to cut most non-metal materials, such 30mm acrylic, perspex, 15mm wood, 12mm MDF, plastic, paper, cardboard, PVC, rubber, cloth, leather, etc. and 1.5mm stainless steel, carbon steel.

Front panel Ruida 6332M,you could adjust cutting speed and power from here.

Color screen on the right side of the machine, you can switch metal cutting and nonmetal cutting from here.

Blade work table with tweezers anti-static from machine, blade table suitable for hard materials, such as acrylic, wood, steel, spong, etc.

Control software:

RD MetalCut is easy to coperate User-friendly

Compatible software: Coreldraw and Autocad

Control software language :English/Chinese

Software environment : Windows xp/7/8/10

Graphic formats: DST,PLT,DXF,AI,LAS,BMP,JPG,PNG,etc

Optional:

Optional:Panasonic / Yaskawa servo motor & driver + TBI ballscrew / Helical gear rack.

Packing:

Delivery time 7--12 working days after received the deposit

Delivery time 7--12 working days after received the deposit sollutions for clients, this machine install 2 heads, 280W laser for cutting metal & thickness nonmetal materials, 60W for engraving objects. It can solve that use too strong power tube for engraving to harm laser tube lifetime problem.Applicable Industry:1. Mixed-cut: metal-Stainless steel,carbon steel and non-metal-acrylic,board.2. High precision: Adopt Leadshine 573S15-L stepper motor with PMI MSA-25R Linear Rail transmission greatly improve the response speed & cutting precision of equipment, extend the time of using.3. Constant light system :The machine uses the constant light,achieving high precision cutting of the whole area.4. High precision and stability: with precision Fulo belt & PMI Linear Rail transmission mechanism and optimized the Ruida RDC 6332M system control, it can meet the precision parts processing ,stable dynamic performance, also can work for long hours.5. The cutting section with good quality: mechanical follow-up cutting head system : cutting head always follow the material to keep the cutting point location unchanged, which insures smooth cutting section without processing again .It can adapt to flat or curved surface sheet cutting.6. Adopt Yongli-280W + 60W sealed CO2 laser tube, main consumable items are electric energy, water-cooling,auxiliary gas and laser light.7. Sample structure,easy operation ,stable laser device and low maintenance cost.Applicable Material:1) Applicable industry:Mainly used for advertising industry (stainless metal and carbon steel),sheet metal industry (carbon steel ),packaging industry (die board) and so on .2) Applicable materials:acrylic, stainless steel ,carbon steel,MDF,die board.3) Applicable show: metal spectable frame,furniture plate cutting,MDF photo frame cutting, building model cutting.Parameters:Model GW-1325MEngraving and Cutting Area 1300*2500mmTube type CO2 sealed glass tubeLaser wave 10.6umLaser Power Yongli-280W + 60WCooling Pure water cycle (water chiller) CW6000Engraving Speed 0-60,000mm/minCutting Speed 0-30,000mm/minReposition Accuracy ±0.01mmMinimum Character Size English:1mm ; Arabic numbers:1mmResolution 1,000--10,000 dpiFile output mode 2.0 USB interfaceMachine Power <3,700WSupport Format and Software PLT,DST,DXF,DWG.CDR, AI, Auto CAD, Coreldraw, Photoshop, laser cut 5.3Working Environment Temperature 0-45°CDrive system Leadshine stepper motor 573S-15L + 3M bletControl system Ruida 6332M DSP offline control systemTransmission way PMI Linear Rail (X aixs MSA-25R, Y axis MSA-20R)Exhaust smoke system 550W exhaust fanWorking Voltage 220V,50HZ/60HZN.W. 1200KGG.W. 1300KGWarranty time 2 years for machine, 10 months for tubePackage Plywood case with steel tubePacking size 4100*2260*1500mmDelivery time 7--12 working days after received the depositNew sollutions for clients, this machine install 2 heads, 280W laser for cutting metal & thickness nonmetal materials, 60W for engraving objects. It can solve that use too strong power tube for engraving to harm laser tube lifetime problem.Applicable Industry:1. Mixed-cut: metal-Stainless steel,carbon steel and non-metal-acrylic,board.2. High precision: Adopt Leadshine 573S15-L stepper motor with PMI MSA-25R Linear Rail transmission greatly improve the response speed & cutting precision of equipment, extend the time of using.3. Constant light system :The machine uses the constant light,achieving high precision cutting of the whole area.4. High precision and stability: with precision Fulo belt & PMI Linear Rail transmission mechanism and optimized the Ruida RDC 6332M system control, it can meet the precision parts processing ,stable dynamic performance, also can work for long hours.5. The cutting section with good quality: mechanical follow-up cutting head system : cutting head always follow the material to keep the cutting point location unchanged, which insures smooth cutting section without processing again .It can adapt to flat or curved surface sheet cutting.6. Adopt Yongli-280W + 60W sealed CO2 laser tube, main consumable items are electric energy, water-cooling,auxiliary gas and laser light.7. Sample structure,easy operation ,stable laser device and low maintenance cost.Applicable Material:1) Applicable industry:Mainly used for advertising industry (stainless metal and carbon steel),sheet metal industry (carbon steel ),packaging industry (die board) and so on .2) Applicable materials:acrylic, stainless steel ,carbon steel,MDF,die board.3) Applicable show: metal spectable frame,furniture plate cutting,MDF photo frame cutting, building model cutting.Parameters:Model GW-1325MEngraving and Cutting Area 1300*2500mmTube type CO2 sealed glass tubeLaser wave 10.6umLaser Power Yongli-280W + 60WCooling Pure water cycle (water chiller) CW6000Engraving Speed 0-60,000mm/minCutting Speed 0-30,000mm/minReposition Accuracy ±0.01mmMinimum Character Size English:1mm ; Arabic numbers:1mmResolution 1,000--10,000 dpiFile output mode 2.0 USB interfaceMachine Power <3,700WSupport Format and Software PLT,DST,DXF,DWG.CDR, AI, Auto CAD, Coreldraw, Photoshop, laser cut 5.3Working Environment Temperature 0-45°CDrive system Leadshine stepper motor 573S-15L + 3M bletControl system Ruida 6332M DSP offline control systemTransmission way PMI Linear Rail (X aixs MSA-25R, Y axis MSA-20R)Exhaust smoke system 550W exhaust fanWorking Voltage 220V,50HZ/60HZN.W. 1200KGG.W. 1300KGWarranty time 2 years for machine, 10 months for tubePackage Plywood case with steel tubePacking size 4100*2260*1500mmDelivery time 7--12 working days after received the deposit

sollutions for clients, this machine install 2 heads, 280W laser for cutting metal & thickness nonmetal materials, 60W for engraving objects. It can solve that use too strong power tube for engraving to harm laser tube lifetime problem.Applicable Industry:1. Mixed-cut: metal-Stainless steel,carbon steel and non-metal-acrylic,board.2. High precision: Adopt Leadshine 573S15-L stepper motor with PMI MSA-25R Linear Rail transmission greatly improve the response speed & cutting precision of equipment, extend the time of using.3. Constant light system :The machine uses the constant light,achieving high precision cutting of the whole area.4. High precision and stability: with precision Fulo belt & PMI Linear Rail transmission mechanism and optimized the Ruida RDC 6332M system control, it can meet the precision parts processing ,stable dynamic performance, also can work for long hours.5. The cutting section with good quality: mechanical follow-up cutting head system : cutting head always follow the material to keep the cutting point location unchanged, which insures smooth cutting section without processing again .It can adapt to flat or curved surface sheet cutting.6. Adopt Yongli-280W + 60W sealed CO2 laser tube, main consumable items are electric energy, water-cooling,auxiliary gas and laser light.7. Sample structure,easy operation ,stable laser device and low maintenance cost.Applicable Material:1) Applicable industry:Mainly used for advertising industry (stainless metal and carbon steel),sheet metal industry (carbon steel ),packaging industry (die board) and so on .2) Applicable materials:acrylic, stainless steel ,carbon steel,MDF,die board.3) Applicable show: metal spectable frame,furniture plate cutting,MDF photo frame cutting, building model cutting.Parameters:Model GW-1325MEngraving and Cutting Area 1300*2500mmTube type CO2 sealed glass tubeLaser wave 10.6umLaser Power Yongli-280W + 60WCooling Pure water cycle (water chiller) CW6000Engraving Speed 0-60,000mm/minCutting Speed 0-30,000mm/minReposition Accuracy ±0.01mmMinimum Character Size English:1mm ; Arabic numbers:1mmResolution 1,000--10,000 dpiFile output mode 2.0 USB interfaceMachine Power <3,700WSupport Format and Software PLT,DST,DXF,DWG.CDR, AI, Auto CAD, Coreldraw, Photoshop, laser cut 5.3Working Environment Temperature 0-45°CDrive system Leadshine stepper motor 573S-15L + 3M bletControl system Ruida 6332M DSP offline control systemTransmission way PMI Linear Rail (X aixs MSA-25R, Y axis MSA-20R)Exhaust smoke system 550W exhaust fanWorking Voltage 220V,50HZ/60HZN.W. 1200KGG.W. 1300KGWarranty time 2 years for machine, 10 months for tubePackage Plywood case with steel tubePacking size 4100*2260*1500mmDelivery time 7--12 working days after received the depositNew sollutions for clients, this machine install 2 heads, 280W laser for cutting metal & thickness nonmetal materials, 60W for engraving objects. It can solve that use too strong power tube for engraving to harm laser tube lifetime problem.Applicable Industry:1. Mixed-cut: metal-Stainless steel,carbon steel and non-metal-acrylic,board.2. High precision: Adopt Leadshine 573S15-L stepper motor with PMI MSA-25R Linear Rail transmission greatly improve the response speed & cutting precision of equipment, extend the time of using.3. Constant light system :The machine uses the constant light,achieving high precision cutting of the whole area.4. High precision and stability: with precision Fulo belt & PMI Linear Rail transmission mechanism and optimized the Ruida RDC 6332M system control, it can meet the precision parts processing ,stable dynamic performance, also can work for long hours.5. The cutting section with good quality: mechanical follow-up cutting head system : cutting head always follow the material to keep the cutting point location unchanged, which insures smooth cutting section without processing again .It can adapt to flat or curved surface sheet cutting.6. Adopt Yongli-280W + 60W sealed CO2 laser tube, main consumable items are electric energy, water-cooling,auxiliary gas and laser light.7. Sample structure,easy operation ,stable laser device and low maintenance cost.Applicable Material:1) Applicable industry:Mainly used for advertising industry (stainless metal and carbon steel),sheet metal industry (carbon steel ),packaging industry (die board) and so on .2) Applicable materials:acrylic, stainless steel ,carbon steel,MDF,die board.3) Applicable show: metal spectable frame,furniture plate cutting,MDF photo frame cutting, building model cutting.Parameters:Model GW-1325MEngraving and Cutting Area 1300*2500mmTube type CO2 sealed glass tubeLaser wave 10.6umLaser Power Yongli-280W + 60WCooling Pure water cycle (water chiller) CW6000Engraving Speed 0-60,000mm/minCutting Speed 0-30,000mm/minReposition Accuracy ±0.01mmMinimum Character Size English:1mm ; Arabic numbers:1mmResolution 1,000--10,000 dpiFile output mode 2.0 USB interfaceMachine Power <3,700WSupport Format and Software PLT,DST,DXF,DWG.CDR, AI, Auto CAD, Coreldraw, Photoshop, laser cut 5.3Working Environment Temperature 0-45°CDrive system Leadshine stepper motor 573S-15L + 3M bletControl system Ruida 6332M DSP offline control systemTransmission way PMI Linear Rail (X aixs MSA-25R, Y axis MSA-20R)Exhaust smoke system 550W exhaust fanWorking Voltage 220V,50HZ/60HZN.W. 1200KGG.W. 1300KGWarranty time 2 years for machine, 10 months for tubePackage Plywood case with steel tubePacking size 4100*2260*1500mmDelivery time 7--12 working days after received the deposit

- Related Products

- [Return Home] [Print] [Go Back]

Products Search

Brand Zone

Contact Us

Contact Person:

Godwin GaoTel:

+8615553103090 ; 13296418707Fax:

E-mail:

info@god-worker.com- sales@god-worker.com