News

SOLUTIONS IN SHOES, LEATHER AND BAG INDUSTRY

- 2014-09-23 15:31:29

-

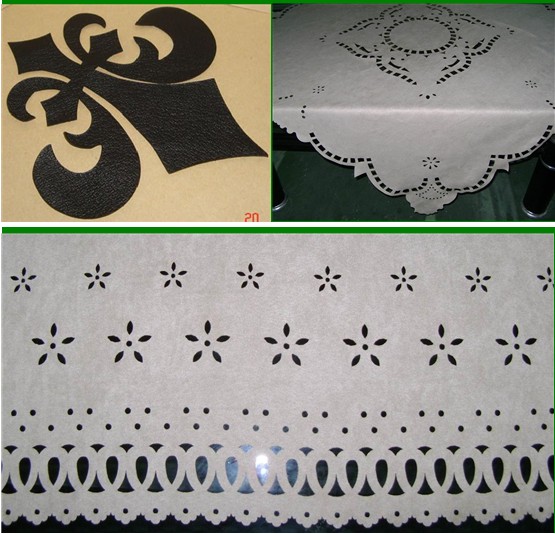

Solution Flow: Bag design, shoes design, pattern making → cutting software → Ruida / Leetro laser Model Cutting →ERPSoftware Introduction for Material Cutting:Original Material Input: Input sample design to computer by using digital device or scanner.Assistant Design: auto-edging, auto-pointing, arbitrary division,arbitrary combination, set property,combine. model No, image design.Image Operation: Move, delete, copy, rotate,zoom in, edit.Parameter Setup: Providing current item parameter and targeted parameter,as well as six shoes number.Zoom: Atuo-zoom from a small size to a big size within several seconds.Synchronous Operation: Scanning sample, editting sample, cutting sample areoperated synchronously.History Records: Saving shoes design details for future reference or revising new designs.Application Field: Leather shoes, cloth shoes, rubber shoes, sports shoes, plastic shoes, knife mold factory, shoe sole factory and so on.CAD System Features in 3D Shoes Design:Design shoe lines on waist area.Display 2D whole image into the software.Options for multi-slicing color and sticking material by piece.Simple design operation.Usable in traditional big size and popular shoe sole.Easy light adjustment.Output design to 3D software to see.Solution Features for Bag Cutting:Specially designed for bag industry, it can solve the problems of all kinds of boxes, backpacks and mountain bags. User-friendly and it enables designers to use at will.Powerful pleating function, such as parallel fold, multi-layer fold and so on, perfect the design of handbags.Featured place seam function. Combining the function of magic ink, you can also make different beginning seamed finish according to different demands. 90% effect can be realized by this.Providing sample database for designers. It makes using of sample plate and shared plate more convenient, enhance working efficiency greatly and lesson the burden of designers.Auto nesting and manual nesting are both provided. After choosing nesting, you will know material usage rate and size, reducing errors under reasonable and scientific management.Perimeter and area of paper pattern can be calculated automatically in our system, which can be output to EXCEL format file to count the cost of materials of every paper pattern, then give quotations.

Solution Flow: Bag design, shoes design, pattern making → cutting software → Ruida / Leetro laser Model Cutting →ERPSoftware Introduction for Material Cutting:Original Material Input: Input sample design to computer by using digital device or scanner.Assistant Design: auto-edging, auto-pointing, arbitrary division,arbitrary combination, set property,combine. model No, image design.Image Operation: Move, delete, copy, rotate,zoom in, edit.Parameter Setup: Providing current item parameter and targeted parameter,as well as six shoes number.Zoom: Atuo-zoom from a small size to a big size within several seconds.Synchronous Operation: Scanning sample, editting sample, cutting sample areoperated synchronously.History Records: Saving shoes design details for future reference or revising new designs.Application Field: Leather shoes, cloth shoes, rubber shoes, sports shoes, plastic shoes, knife mold factory, shoe sole factory and so on.CAD System Features in 3D Shoes Design:Design shoe lines on waist area.Display 2D whole image into the software.Options for multi-slicing color and sticking material by piece.Simple design operation.Usable in traditional big size and popular shoe sole.Easy light adjustment.Output design to 3D software to see.Solution Features for Bag Cutting:Specially designed for bag industry, it can solve the problems of all kinds of boxes, backpacks and mountain bags. User-friendly and it enables designers to use at will.Powerful pleating function, such as parallel fold, multi-layer fold and so on, perfect the design of handbags.Featured place seam function. Combining the function of magic ink, you can also make different beginning seamed finish according to different demands. 90% effect can be realized by this.Providing sample database for designers. It makes using of sample plate and shared plate more convenient, enhance working efficiency greatly and lesson the burden of designers.Auto nesting and manual nesting are both provided. After choosing nesting, you will know material usage rate and size, reducing errors under reasonable and scientific management.Perimeter and area of paper pattern can be calculated automatically in our system, which can be output to EXCEL format file to count the cost of materials of every paper pattern, then give quotations.

- Previous [Return Home] [Print] [Go Back] Next

Products Search

Brand Zone

Contact Us

Contact Person:

Godwin GaoTel:

+8615553103090 ; 13296418707Fax:

E-mail:

info@god-worker.com- sales@god-worker.com